Chemical reactor

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

Germany

Germany

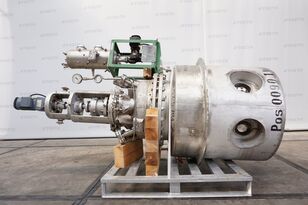

* Exterior color: Painted green

* H: 90 cm

* L: 145 cm

* B: 80 cm

* Weight: approx. 366 kg

* Stuff: Enamelled steel (inside)

* Exterior color: Painted green

* H: 90 cm

* L: 145 cm

* B: 80 cm

* Weight: approx. 366 kg

For sale is a used, heavy enamelled pressure vessel with agitator connection, presumably part of a reactor system. The vessel is equipped with several process nozzles, flanges, and a central drive flange for a stirring mechanism. It is ideally suited for aggressive media and processes in the chemical, pharmaceutical, or food industries. The system consists of the components shown in the images.

Advantages:

- High-quality enamel lining – resistant to acids, bases and solvents

- Robust industrial design with multiple process connections

- Central agitator flange (approx. Ø 100 mm)

- Wide range of connections (DN50, DN80, etc.)

- Sustainable and economical alternative to new purchases

---------------------------------------------------------------

General functions:

- Pressure/reaction vessels for aggressive, corrosive media

- Enamel-coated interior (white/blue visible)

- Flange connections for agitator, filling material, emptying, sensors

- Side flange flaps with the designation "M2016" (presumably safety valve or blind flange according to DIN)

- With lifting eyes and stable base frame construction

- Used, functional

- No visible damage to the enamel

- Connection flanges complete

- Visually in good condition, mountable

Scope of delivery:

- Container with all visible flange connections and enamelling, as shown

---------------------------------------------------------------

CO₂ savings:

By reusing an enamelled pressure vessel, CO₂-intensive manufacturing processes such as steel casting, enamel coating and mechanical processing are eliminated.

? Estimated CO₂ savings: approx. 1,100 – 1,400 kg CO₂, which corresponds to approximately 11,000–14,000 km of driving with a mid-range car.

---------------------------------------------------------------

Device details (type plate data in German):

- Design: Horizontally lying pressure or reaction vessel

- Material: Enamelled steel (inside)

- Flange connections (visible):

- 1× Stirrer flange Ø approx. 100 mm

- Several process nozzles (DN 50 / DN 80 estimated)

- Inlet and outlet openings, arranged centrally and tangentially.

- Side information: M2016 (presumably component identifier of the flange / fitting)

* Farbe außen: Grün lackiert

* H: 90 cm

* L: 145 cm

* B: 80 cm

* Gewicht: ca. 366 kg

Zum Verkauf steht ein gebrauchter, schwerer emailierter Druckbehälter mit Rührwerksanschluss, vermutlich Teil eines Reaktorsystems. Der Behälter ist mit mehreren Prozessstutzen, Flanschen sowie einem zentralen Mitnehmerflansch für einen Rührantrieb ausgestattet. Er eignet sich ideal für aggressive Medien und Prozesse in der Chemie-, Pharma- oder Lebensmittelindustrie. Die Anlage besteht aus den Teilen, die in den Bildern zu sehen sind.

Vorteile:

- Hochwertige Emailleauskleidung – beständig gegen Säuren, Basen und Lösungsmittel

- Robuste Industrieausführung mit mehreren Prozessanschlüssen

- Zentraler Rührwerksflansch (ca. Ø 100 mm)

- Große Anschlussvielfalt (DN50, DN80 u. a.)

- Nachhaltige und wirtschaftliche Alternative zur Neuanschaffung

---------------------------------------------------------------

Allgemeine Funktionen:

- Druck-/Reaktionsbehälter für aggressive, korrosive Medien

- Innen emaillebeschichtet (weiß/blau sichtbar)

- Flanschanschlüsse für Rührwerk, Füllgut, Entleerung, Sensorik

- Seitlich Flanschklappen mit Bezeichnung „M2016“ (vermutlich Sicherheitsventil oder Blindflansch nach DIN)

- Mit Hebeösen und stabiler Grundrahmenaufstellung

- Gebraucht, funktional

- Keine sichtbaren Schäden an der Emaille

- Anschlussflansche vollständig

- Optisch in gutem Zustand, montierbar

Lieferumfang:

- Behälter mit allen sichtbaren Flanschanschlüssen und Emaillierung, wie abgebildet

---------------------------------------------------------------

CO₂-Einsparung:

Durch Wiederverwendung eines emaillierten Druckbehälters entfallen CO₂-intensive Herstellprozesse wie Stahlguss, Emaillebeschichtung und mechanische Bearbeitung.

? Geschätzte CO₂-Einsparung: ca. 1.100 – 1.400 kg CO₂, was etwa 11.000–14.000 km Fahrleistung mit einem Mittelklassewagen entspricht.

---------------------------------------------------------------

Gerätedetails (Typenschilddaten auf Deutsch):

- Bauform: Horizontal liegender Druck- oder Reaktionsbehälter

- Material: Stahl emailliert (innen)

- Flanschanschlüsse (sichtbar):

- 1× Rührwerksflansch Ø ca. 100 mm

- Mehrere Prozessstutzen (DN 50 / DN 80 geschätzt)

- Ein- und Auslauföffnung, mittig und tangential angeordnet

- Seitliche Angabe: M2016 (vermutlich Bauteilkennung des Flansches / Armatur)