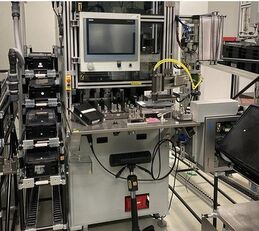

Test Reasearch Inc TR7550 other industrial equipment

PDF

Share

Facebook

WhatsApp

Viber

Telegram

Interested in the ad?

1/2

PDF

Share

Facebook

WhatsApp

Viber

Telegram

Price:

on request

Ask for price

Contact the seller

Year of manufacture:

2011

Location:

Switzerland Location:basel

Location:basel

Seller stock ID:

755527

Placed on:

Feb 27, 2025

Condition

Condition:

used

Additional services

Vehicle delivery service

Important

This offer is for guidance only. Please request more precise information from the seller.

Purchase tips

Seller's contacts

Subscribe to seller

Nick Breinfalk

Languages:

English, German

Address

Switzerland, Location:basel

Seller's local time:

06:13 pm (CET)

Send message

Seller's contacts

UCY Machines

Switzerland

Switzerland

2 years at Machineryline

5.0

64 reviews

Subscribe to seller

+49 89 380...

Show

+49 89 38031644

Ask the seller

PDF

Share

Facebook

WhatsApp

Viber

Telegram

Selling machinery or vehicles?

You can do it with us!

Similar ads

Price on request

2012

Power

2.04 HP (1.5 kW)

Contact the seller

Price on request

2014

Power

61.18 HP (44.97 kW)

Contact the seller

€1,000

Excluding VAT

2007

Power

20 HP (14.7 kW)

Contact the seller

Price on request

Contact the seller

Price on request

2017

Contact the seller

Price on request

Contact the seller

€2,297

PLN 9,600

Power

2.99 HP (2.2 kW)

Fuel

electro

Contact the seller

Marke: Test Reasearch Inc

The Test Research Inc. (TRI) TR7550

introduced around 2010

is an Automated Optical Inspection (AOI) system designed for high-speed

inline inspection of printed circuit boards (PCBs) in electronics manufacturing. It utilizes a top-view 3-CCD color camera and four angled cameras to optimize test coverage

employing TRI's dynamic imaging technology to minimize vibrations and provide accurate

stable inspections before and after reflow soldering processes

Key features of the TR7550 include

High-Speed Inline Color AOI

Ensures comprehensive inspection coverage

Precise 3-CCD Color Camera

Capable of inspecting 01005 fine-pitch components

Advanced RGB+W Lighting System

Enhances detection of solder and markings

Linear Motor X-Y Table

Provides vibration-free

accurate inspection

The system is suitable for inspecting various component defects such as missing components

tombstoning

billboarding

polarity issues

rotation

shift

wrong marking (OCV)

defective components

upside-down placement

lifted components

solder excess

insufficient solder

bridging

through-hole pins

lifted leads

and golden finger scratches or contamination

Find more here

show contacts

Contact us at

show contacts